Services

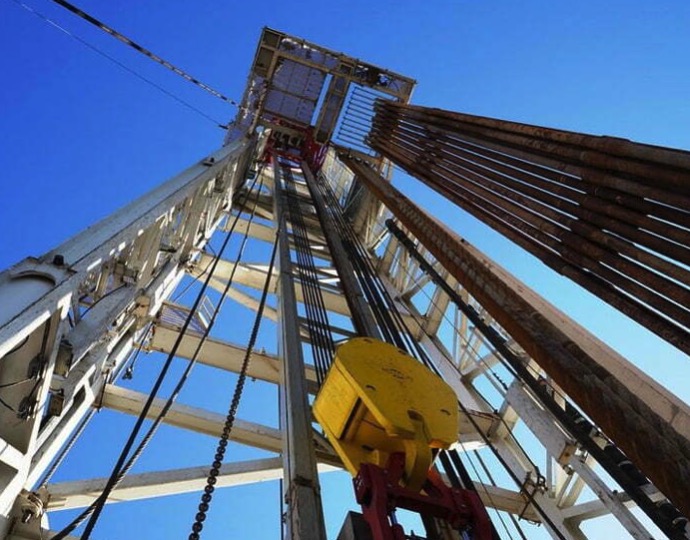

OCTG & RIG INSPECTIONS

Our OCTG & RIG Inspection Team includes Inspection engineers specially trained and experienced to provide OCTG Inspection, NDT, Lifting Gears and Load testing, DROPS Survey, Derrick and Substructure with Rope Access. They are backed by our Advanced Rig Inspection Division which provides support on Drilling & Workover RIG Operational Inspection requirements

- CASING AND TUBING INSPECTIONS

- COILED TUBING INSPECTION

- DRILL PIPE INSPECTIONS & SERVICES (INSPECTED TO API AND DS 1 REQUIREMENTS)

- BHA/HWDP INSPECTIONS

- LIFTING GEAR/LOAD TEST INSPECTION

- RIG COMPONENTS, RIG PARTS AND HANDLING TOOLS INSPECTION

- DOWN HOLE TOOLS INSPECTIONS

- DERRICK INSPECTIONS AND REMEDIAL

- DROPPED OBJECTS PREVENTION SCHEME (DROPS SURVEY INSPECTION)

- YARD MANAGEMENT

Casing and Tubing Inspections

- API full length drifting

- EMI on full body for Tubings

- FLMPI on Casings

- End area Inspections

- Gauging services

- Wall thickness measurements

- Rattling & Blasting services

- OD Buffing Services

- Maintenance services

- Hydro jetting services

- Retrieved Tubing / Casing Inspections

- Sucker Rod Inspection

- Bucking Services

- Classification

- PMI Services

Coiled Tubing Inspection

Our new system for detecting transverse flaws and three dimensional defects in the tubing metal.

- OVALITY INSPECTION

- OUTER DIAMETER INSPECTION

- WALL THICKNESS MONITORING

- METAL LOSS & MFL AMPLITUDE

Drill Pipe Inspections & Services

- End area Inspections (VTI / Black light / Dimensions)

- Visual Inspection. OD Gauging & Thread gauging

- Dimensional Inspection

- UT Connection Inspection (Compression wave technique)

- EMI on full body

- U.T. Wall Thickness measurement and U.T. (Shear Wave) inspection on full body

- Heat checking inspection

- Visual Hard banding inspection

- End area Ultrasonic Inspections (Slip area MPI & Ultrasonic inspection)

- Refacing Services for RSC Joints

- Straightening Services

- ID cleaning with rattling

- OD Cleaning with External Buffing Machine

BHA/HWDP Inspections

- End area Inspections (VTI/Black light/LPT/Dimensions)

- Visual Inspection & Thread Gauging

- UT Connection Inspection (Compression wave technique)

- Dimensional inspection

- Liquid Dye Penetrant Inspection

- HWDP Centre wear pad inspections

- Drill Collar Slip & Elevator groove Inspection

- Upset & Critical Area Inspection

- Heat Checking

Lifting Gear/load Test Inspection

- Lifting Gear Inspections (MPI/ Load Testing / recertification) as per required International Standards

- Inspection and certification of loose lifting equipment

- Fixed equipment Testing and certification

- Provision of Lifting Gear Register

Down Hole Tools Inspections

BHA at Rig site and Shop Inspection for customer/rental tools Inspection of various speciality tools used in the Drilling & Workover Rig operations

- Visual Inspection & Thread Gauging

- Dimensional inspection

- Full Body MPI/ LPT Inspection

- End area Inspections (VTI / Black light/LPT/ Dimensions)

- UT Connection Inspection (Compression wave technique)

- Liquid Dye Penetrant Inspection

Rig Components, Rig Parts and Handling Tools Inspection

- MPI / Black Light (wet Florescent) and White contrast ink inspections

- Ultrasonic Shear wave Inspections

- MPI / Eddy Current on Drilling/Hoisting & Rotary Tools

- Liquid Dye Penetrant Inspection

- Inspection on stressed and critical areas

- Dimensional check

- MPI/Eddy Current Inspection on Miscellaneous Equipmen

Yard Management

- Inspection and Maintenance of Tubular (OCTG) and related equipment

- Periodical Maintenance & preservation program

- Inventory management

- Ensuring proper identification and stacking of OCTG Pipes

- Preparation of OCTG for movement as per Drilling Plans

- Nominated dedicated supervisor to coordinate with Rig and arrange the tools mobilization and receiving

Dropped Objects Prevention Scheme (Drops Survey Inspection)

- DROP inspection for all Drilling & Workover Rig zones

- Survey Report-A compilation of assessments and specific equipment inspections resulting in the Dropped Object Survey.

- Fail Item List – A list of remedial actions required based on equipment inspections or surveys

Derrick Inspections and Remedial

Inspections as per API RP 4G requirements- Category 3

- Inspection of Mast/Derrick and accessories

- Sub Structures and accessories

- Crown Block Sheaves and Bearing inspection

- Derrick Remedial

- 100% Bolt Check